At PEI Limited, our proven commitment to engineering excellence drives us to deliver top-tier solutions for the dairy, forestry, petrochemical, marine, and healthcare industries across the South Island of New Zealand. As part of our expanding engineering business we are proud to introduce ValveTech, our specialised division focused on industrial valve engineering, service, testing and maintenance. We service in house or on the customers sites whatever the requirements are.

Why Choose ValveTech?

Cutting-Edge Workshop Facilities

Our expansive workshop facility is based in Rolleston, Christchurch, and is the heart of ValveTech. Here, our experienced team works with state-of-the-art equipment to meet your most demanding industrial valve engineering needs. Our Christchurch base places us in an ideal position to be able to service industries from the dairy farm strongholds of Canterbury and Southland, to the specialist viticulture and food processing plants of the Tasman and Marlborough regions. From large scale petrochemical and marine valve servicing, right down to precision healthcare valve engineering, machining and tooling, our workshop keeps the life blood of New Zealand’s industry flowing.

Specialised Equipment

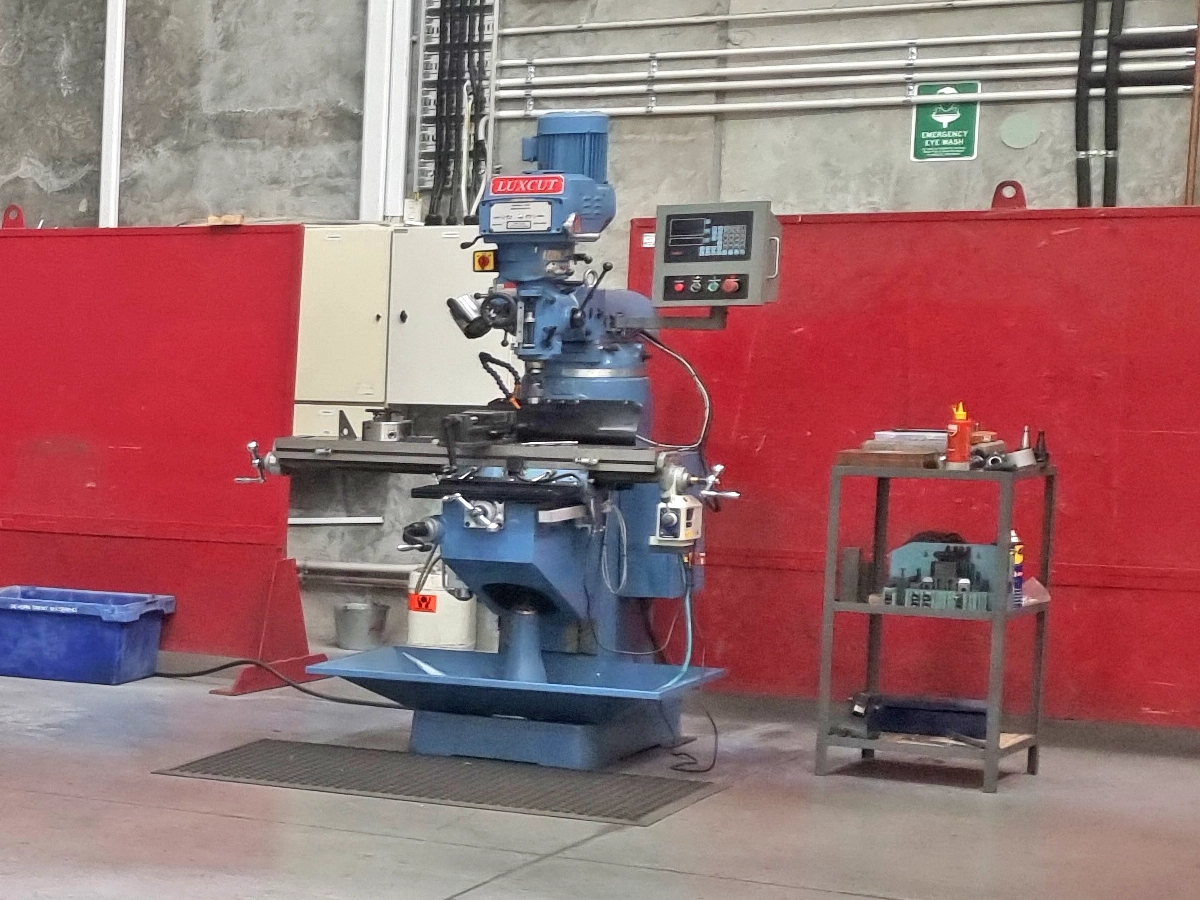

Industrial Lathes and Milling Machines

Our skilled technicians operate industrial lathes and milling machinery to the high standards that we hold ourselves accountable to, meeting the quality of workmanship that our existing clients expect and our new clients are delighted by. We can create small batch mechanical parts right through to large-scale valve refurbishment or modifications, whether it’s shaping intricate components or ensuring precise tolerances, we can shape, modify, and deliver ready for our team to install on site.

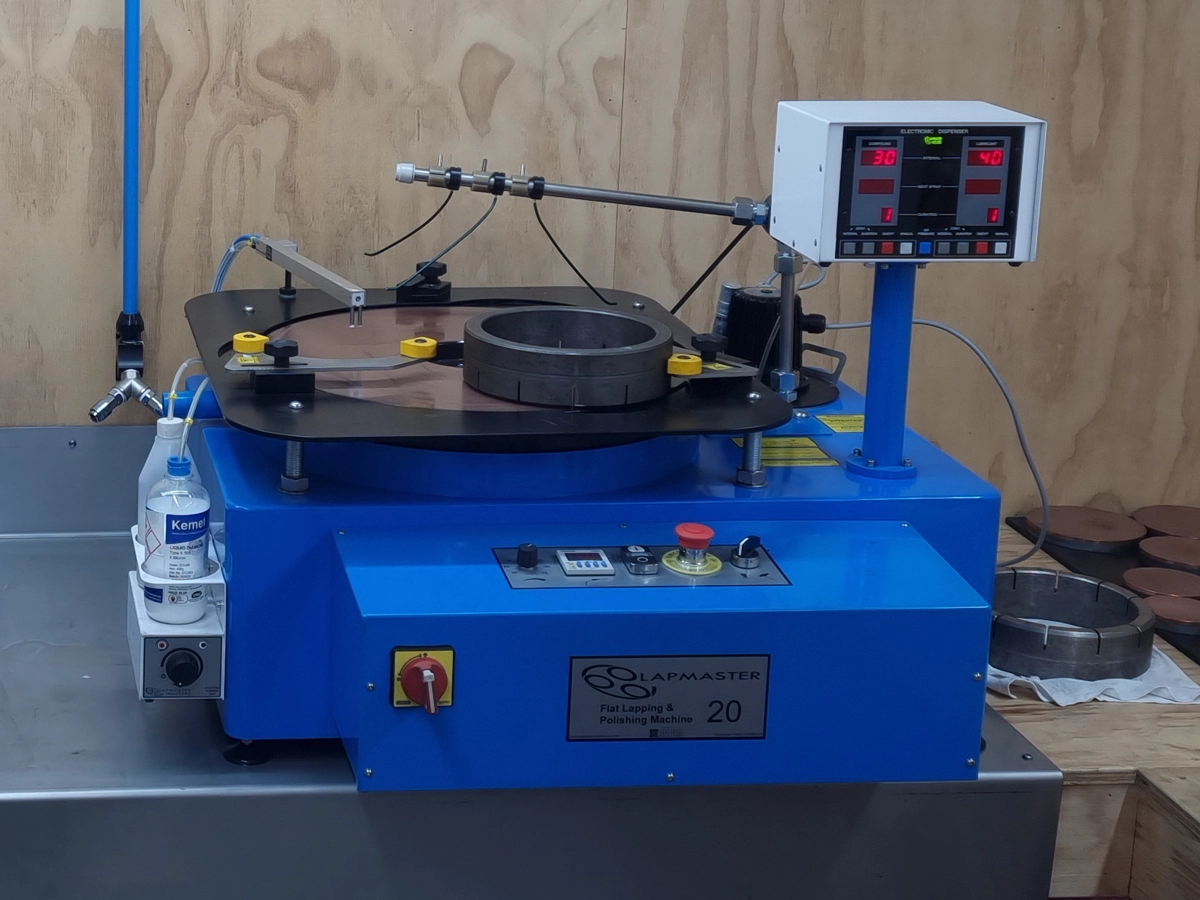

Lapmaster Precision Cast Iron and Diamond Machining

Your valve discs and seats demand perfection. Our Lapmaster machines, utilising single-wavelength illumination have the ability to lap valve discs and seats to achieve surface flatness within 1 lightband or 0.0000254mm. It’s this level of precision your projects deserve and we pride ourselves on delivering. Our Lapmaster precision cast iron plates offer a variety of lapping and polishing surfaces for almost any application and our use of diamond slurry produces reflective finishes on a wide variety of materials.

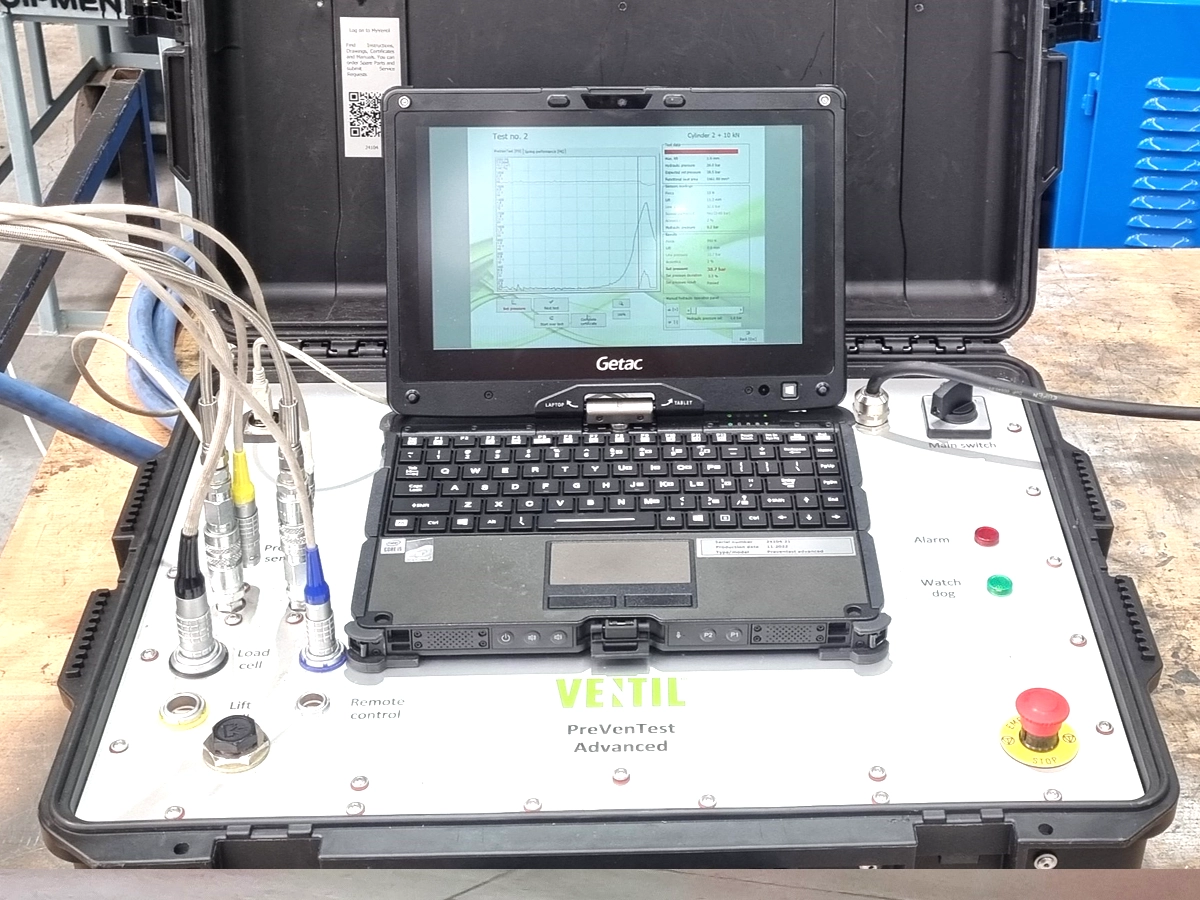

Accredited Safety Valve Testing

At Valvetech we believe the health and safety of all individuals within the work environment must never be compromised and the same goes for the quality of the materials and workmanship we provide.

We are an IANZ Endorsed Testing Laboratory to ISO17025. Our manual and fully automated pneumatic safety valve testing facilities are accredited to test safety valves up to 250barg (size-dependent). We conduct leakage testing to API527 or any other standard specified by our clients. You can read more about our commitment to safety here. We also offer onsite Assisted Lift Certification with our Advanced PreVen safety valve testing machine.

Surface Preparation And Blasting

Garnet Blasting

Prepare surfaces for optimal adhesion. Our garnet blasting process removes impurities, leaving a clean canvas for further treatment.

Sand Blasting

Precision matters. Our sand blasting technique achieves the desired surface finish, ready for the next phase of your project.

Steel Grit Blasting

When durability matters, steel grit blasting delivers. It enhances surface strength, ensuring longevity and structural reliability of the material.

Rigorous Hydrostatic Testing

When you need to evaluate the structural integrity of your pipeline or other pressure-containing infrastructure, our accredited hydrostatic testing facilities can handle pressures up to 550barg. Whether it’s after repair or during a plant shut down trust in ValveTech to ensure your valves and industrial pressure systems perform flawlessly under extreme conditions.

Valve Coating And Painting Facilities

The finishing touch matters. The right coating for your industrial valves is paramount to ensure longevity and protection of the metals. In most cases, with valve surface coatings we are prepping for the reduction of corrosion. However you also need to consider the environment that the valve will be exposed to to ensure the paint applied is resistant to external elements.

Chemical fumes, operating temperatures, insulation materials, even cleaning products will all have an effect on the choice of surface coating applied. In our controlled painting facilities, complete with filtered ventilation, we ensure your valves not only look their best but have the appropriate coatings to withstand the rigours of your plant and environment.

Contact Us Today

If the integrity of your pressure systems is paramount to the safety and continuation of your business, reach out to our friendly team at ValveTech. We’re here to welcome new business, answer your questions, and collaborate with you on solutions that will enhance and provide new efficiencies in your business.